Digital Design Services

Benefit from our tools and insights without having to do the work.

Generation of Digital Twins

We build and validate your digital twin.

Generation of Digital Twin

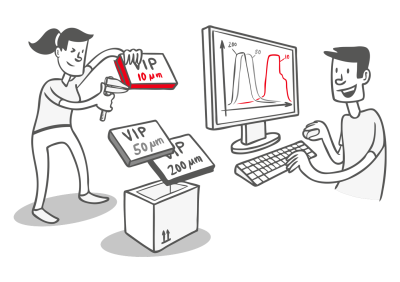

We first build a digital twin of your desired shipping system in accordance to the qualification report or box description provided.

Validation of Digital Twin

We will then validate this digital twin of your shipping system, to prevent discrepancies between the digital and the analogue packaging. For this, we use measurement data, such as provided in qualification reports.

Add Digital Twin to Your Library

We will provide you with the validated digital twin. You can then add it to your model library, and use it in other SmartCAE software modules, e.g. for digital test shipments in the SmartCAE Lane Risk.

Optimization of Passive Shippers

Obtain key factors and values to improve your shippers.

Digital Twin

First, we need a digital twin. If you already have one, we will use it as a basis. If not, we will generate and validate a digital twin of your desired shipping system.

Optimization of Components

By varying different parameters of the digital twin, we then determine, how your physical shipping system could be improved, e.g. to provide a longer lifetime. These parameters could be factors such as the insulation thickness, dimensions, filling, etc.

Dry Ice Shipper Design

Improve your physical dry ice shipper with a digital optimization analysis.

Creation of Digital Twin

If you already have a packaging solution that you would like to use for your dry ice shipments, we first create a digital twin from the physical shipper. If not, we create the digital twin of a standard shipper matching your requirements.

Optimization of Shipper

Starting with the basic digital twin, we then analyze different factors and their effect on the shipper's lifetime. These factors include extra EPS sheets, different dry ice configurations, and more. With the findings of the digital model, you can then directly improve your physical shipper.

Preconditioning of Coolants

Determine the correct preconditioning setting for your coolants.

Importance of Correct Preconditioning

The preconditioning of coolants is critical for a packaging's lifetime. A poorly preconditioned coolant can cause the product to fail, due to freezing or overheating. Knowing the exact setpoints for duration and temperature is important to precondition the coolant to the required state, thus helping avoid temperature excursions in passive shippers.

The Right Time and Temperature

We help you find the right time and temperature to get your desired preconditioning state of the coolants. Aided by digital modelling, we can analyze scenarios like single coolants, coolant stacks, coolants stacked on pallets, and more. Using the simulation results, you get the optimum preconditioning process for your SOP.